Movement challenges often arise in spaces with limited room. Production floors, service corridors, mobile equipment frames, and custom enclosures frequently demand controlled movement without the luxury of wide turning radii. In these environments, casters become more than mobility components; they directly influence efficiency, safety, and equipment usability. When standard caster layouts struggle to perform, alternative mounting strategies become more important.

Side-mounted solutions have emerged as a practical response to these constraints. By shifting how loads are supported and steered, specialized caster configurations help equipment navigate narrow clearances, offsets, and directional limitations that conventional setups cannot address effectively.

Understanding Maneuverability Limitations in Tight Spaces

Maneuverability issues typically arise from restricted turning arcs, limited clearance, and uneven load distribution. Standard caster placements often require space beneath or directly under the load, which is not always available in compact designs. Equipment that must move laterally, pivot within confined spaces, or align precisely with workstations can be difficult to position accurately.

Poor maneuverability also increases handling effort. Operators may need to reposition equipment multiple times, increasing fatigue and the risk of accidental contact with surrounding structures. Over time, these inefficiencies compound into productivity losses and safety concerns.

What Are Side Mount Casters and How Do They Differ from Standard Casters?

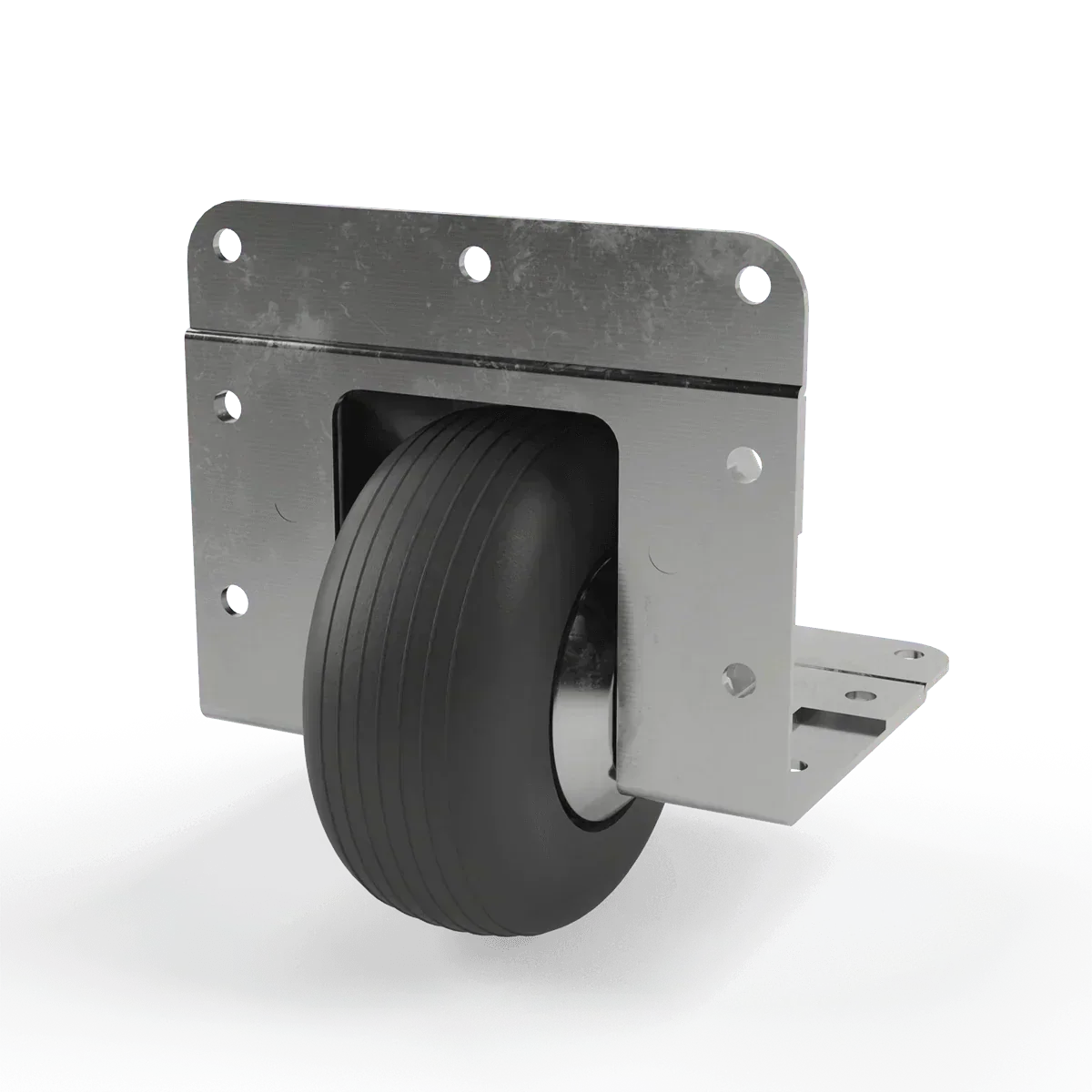

Side-mount casters are installed along the vertical face of a structure rather than directly underneath it. This configuration allows wheels to engage the floor while keeping the load platform lower or unobstructed. Unlike traditional bottom-mountedcaster wheels, side-mounted designs support movement without increasing overall equipment height.

This distinction makes side-mounted solutions particularly valuable where undercarriage space is occupied by components, wiring, or structural reinforcements. The mounting orientation also alters how forces are transferred, enabling smoother directional control in constrained layouts.

Why Side Mount Casters Excel in Tight and Restricted Areas

Side-mounted designs reduce the turning radius required for movement. By positioning the wheel closer to the load’s center of gravity, lateral motion becomes more controlled and predictable. This allows equipment to glide through narrow aisles, doorways, or between fixed installations without excessive repositioning.

Another advantage lies in clearance management. Because the mounting does not rely on bottom clearance, equipment can be designed with minimal ground gaps while still remaining mobile. This is especially beneficial in environments where stability and low-profile designs are essential.

Common Applications That Benefit from Side Mount Casters

Side-mounted caster solutions are widely used in industrial carts, material handling frames, service enclosures, and specialized machinery. Maintenance carts that must slide into tight service bays often rely on this configuration to avoid interference with under-mounted components.

In manufacturing and assembly environments, mobile workstations benefit from improved alignment and reduced footprint. Even applications requiring resilient rolling surfaces frequently integrate arubber caster wheel with side mounting to balance maneuverability with floor protection and noise reduction.

To learn more about the benefits of rubber caster wheels, read our blog here.

Key Design Factors When Using Side Mount Casters

Load capacity remains a primary consideration. Side mounting introduces different stress paths compared to bottom-mounted systems, making proper reinforcement essential. Bracket strength, fastener selection, and mounting surface rigidity all influence long-term performance.

Wheel material selection also plays a critical role. Rubber compounds provide vibration damping and traction, while other materials may prioritize load capacity or chemical resistance. Selecting the right caster wheels ensures consistent performance without compromising maneuverability.

Side Mount Casters vs Other Caster Configurations in Tight Spaces

Swivel casters offer flexibility but often require more space to rotate fully. Rigid casters improve straight-line control but limit directional changes. Side-mounted configurations strike a balance by enabling controlled movement without demanding large turning clearances.

Compared to retractable or lift-style systems, side-mounted designs maintain continuous contact with the floor, ensuring stability during movement. This consistency simplifies handling while reducing mechanical complexity.

How Side Mount Casters Improve Safety and Operator Control

Improved maneuverability directly enhances safety. Equipment that responds predictably to applied force reduces the likelihood of sudden shifts or collisions. Operators can guide loads with smaller inputs, maintaining better control in confined environments.

Lower overall equipment height also contributes to stability. By avoiding tall caster stacks, side-mounted systems help keep the center of gravity low, reducing tipping risk during movement or repositioning.

Common Installation Mistakes That Reduce Maneuverability

Improper alignment is a frequent issue. Casters mounted out of square or without consistent spacing can introduce drag and uneven rolling resistance. Overlooking load distribution may also cause premature wear or directional drift.

Another common oversight involves floor conditions. Even well-designed caster systems perform poorly on damaged or contaminated surfaces. Addressing these factors during installation preserves intended maneuverability benefits.

Maintenance Practices to Keep Side Mount Casters Performing Smoothly

Routine inspection ensures continued performance. Checking fasteners, brackets, and wheel condition helps identify wear before it affects movement. Lubrication schedules should align with operating conditions to prevent binding or noise.

Debris buildup around wheels can compromise rolling efficiency. Regular cleaning maintains smooth travel and extends service life, especially in environments with dust or process residues.

When Side Mount Casters May Not Be the Best Solution

Not every application benefits from side mounting. Extremely heavy loads or environments with significant side impact forces may require alternative configurations. Applications demanding frequent vertical load adjustments may also favor different mobility systems.

Evaluating movement patterns, load dynamics, and environmental conditions ensures the selected caster strategy aligns with operational needs rather than introducing new limitations.

Choosing the Right Caster Strategy for Confined Workspaces

Solving maneuverability challenges in tight spaces requires more than selecting standard mobility components. Side-mounted solutions address clearance, control, and stability issues that often restrict equipment movement. When designed and installed correctly, they enable smoother operation without increasing footprint or complexity.

TCH supports industrial teams in selecting and integrating caster systems that align with real-world constraints. From engineered mounting strategies to application-specific recommendations, TCH helps optimize mobility in limited spaces. Contact us today to identify the right side mount casters for confined workspace applications.