Mobility plays a critical role in how equipment, furniture, and industrial assets function in daily operations. From warehouse carts to medical devices and mobile workstations, casters quietly determine how smoothly loads move, stop, and stay in place. When mobility systems fail, productivity slows, safety risks increase, and equipment wear accelerates.

Understanding how different caster designs work helps prevent these issues. Swivel, rigid, and locking casters are engineered for distinct movement patterns and load behaviors. Selecting the right configuration ensures stable handling, controlled movement, and dependable performance across a wide range of environments.

What Are Caster Wheels?

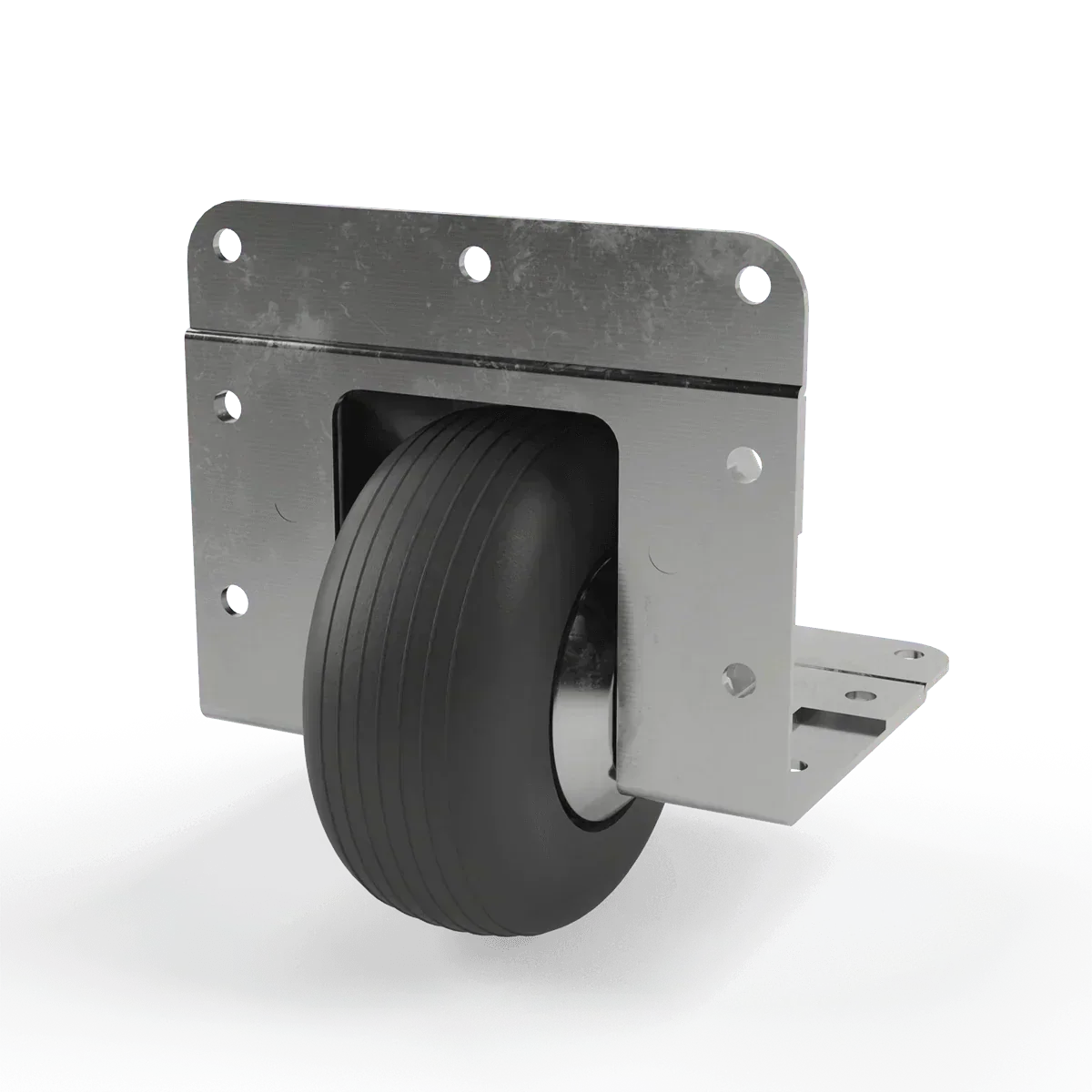

Caster wheels are wheel assemblies mounted to the underside of equipment to enable rolling movement. Each caster typically includes a wheel, mounting hardware, and a frame that supports load transfer while allowing controlled motion.

Used across industrial, commercial, healthcare, and institutional settings, caster wheels reduce manual handling effort while improving maneuverability. Performance depends heavily on design type, materials, load rating, and how the casters are combined on the equipment base.

Key Components of a Caster Wheel Assembly

A caster assembly includes several core components that work together to manage movement and load:

-

Wheel:Contacts the floor surface and carries the load

-

Fork or Yoke: Holds the wheel and connects it to the mounting plate

-

Mounting Plate or Stem: Attaches the caster to the equipment

-

Swivel Bearing (if applicable):Allows rotational movement

-

Brake or Lock (if applicable): Controls motion and stability

Material choice also matters. Arubber caster wheel, for example, provides quiet operation and floor protection, while harder materials offer lower rolling resistance under heavy loads.

1. Swivel Casters: Maximum Maneuverability

Swivel casters rotate 360 degrees, allowing equipment to change direction easily. This design excels in tight spaces where frequent turning and repositioning are required.

Common applications include carts, hospital beds, mobile shelving, and assembly stations. Swivel casters reduce operator effort by enabling multidirectional movement, though excessive swivel can introduce directional instability when used alone on long travel paths.

2. Rigid Casters: Straight-Line Stability

Rigid casters roll only in a straight line, maintaining a fixed direction of travel. This design provides predictable movement and improved control over longer distances.

Facilities often use rigid casters on heavy-duty carts, conveyors, and transport equipment where straight-line motion improves tracking and reduces caster flutter. While turning requires more effort, rigid casters offer superior load stability during continuous movement.

3. Locking Casters: Control, Safety, and Stability

Locking casters combine mobility with controlled positioning. These casters include a braking mechanism that prevents wheel rotation, swivel movement, or both.

Locking casters are essential in environments where equipment must remain stationary during operation. Workbenches, medical devices, and inspection stations often rely on locking casters to maintain precise positioning and improve safety.

Common Locking Mechanisms Explained

Several locking mechanisms are commonly used in caster designs:

-

Wheel Brake: Prevents wheel rotation but allows swivel

-

Swivel Lock: Restricts swivel movement while allowing rolling

-

Total Lock:Locks both wheel rotation and swivel action

Total lock casters offer the highest level of stability and are often preferred for equipment that requires firm placement during use.

Comparing Swivel, Rigid, and Locking Casters

Each caster type offers distinct advantages depending on movement requirements:

-

Swivel casters prioritize maneuverability

-

Rigid casters provide directional control

-

Locking casters add safety and positional stability

Performance improves when these designs are combined strategically rather than used in isolation.

How to Choose the Right Caster Type for Your Application

Selecting the right caster type begins with understanding movement patterns. Equipment that frequently turns or repositions benefits from swivel casters, while long transport runs favor rigid casters.

Load weight, floor conditions, environmental exposure, and noise requirements also influence selection. A rubbercaster wheel is often preferred for finished floors and noise-sensitive areas, while industrial environments may require harder compounds and reinforced frames.

Also read: Exploring the Benefits of Rubber Caster Wheels - Quiet, Safe, and Floor-Friendly

Common Mistakes When Selecting Caster Wheels

Several selection errors reduce caster performance and lifespan:

-

Choosing casters based on load rating alone

-

Ignoring floor surface conditions

-

Using all swivel casters on long-travel equipment

-

Overlooking brake requirements

-

Selecting materials incompatible with environmental exposure

Avoiding these mistakes improves safety, reduces maintenance, and extends service life.

Best Practices for Combining Caster Types

Many applications perform best with a mixed caster configuration. A typical setup uses two swivel casters and two rigid casters, balancing maneuverability with directional stability.

Adding locking casters to swivel positions enhances control without sacrificing flexibility. Proper placement ensures predictable movement while maintaining operational safety.

Choosing the Right Caster Wheels for Long-Term Performance

Reliable mobility depends on understanding how different caster designs influence movement, control, and load handling. Swivel, rigid, and locking casters each serve a specific role, and thoughtful selection prevents premature wear, instability, and operational inefficiencies.

TCH offers engineered caster solutions that are durable, perform well, and meet application-specific demands. From industrial carts to specialized equipment requiring a high-performance rubber caster wheel, the right caster selection makes a measurable difference.

Connect with TCH to source caster wheels built for long-term reliability and controlled mobility.