The modern construction industry is undergoing a

significant transformation, and one material at the forefront of this change is polyethylene foam. This versatile and innovative material is

becoming indispensable in construction projects worldwide, thanks to its unique properties and wide range of

applications.

The modern construction industry is undergoing a

significant transformation, and one material at the forefront of this change is polyethylene foam. This versatile and innovative material is

becoming indispensable in construction projects worldwide, thanks to its unique properties and wide range of

applications.

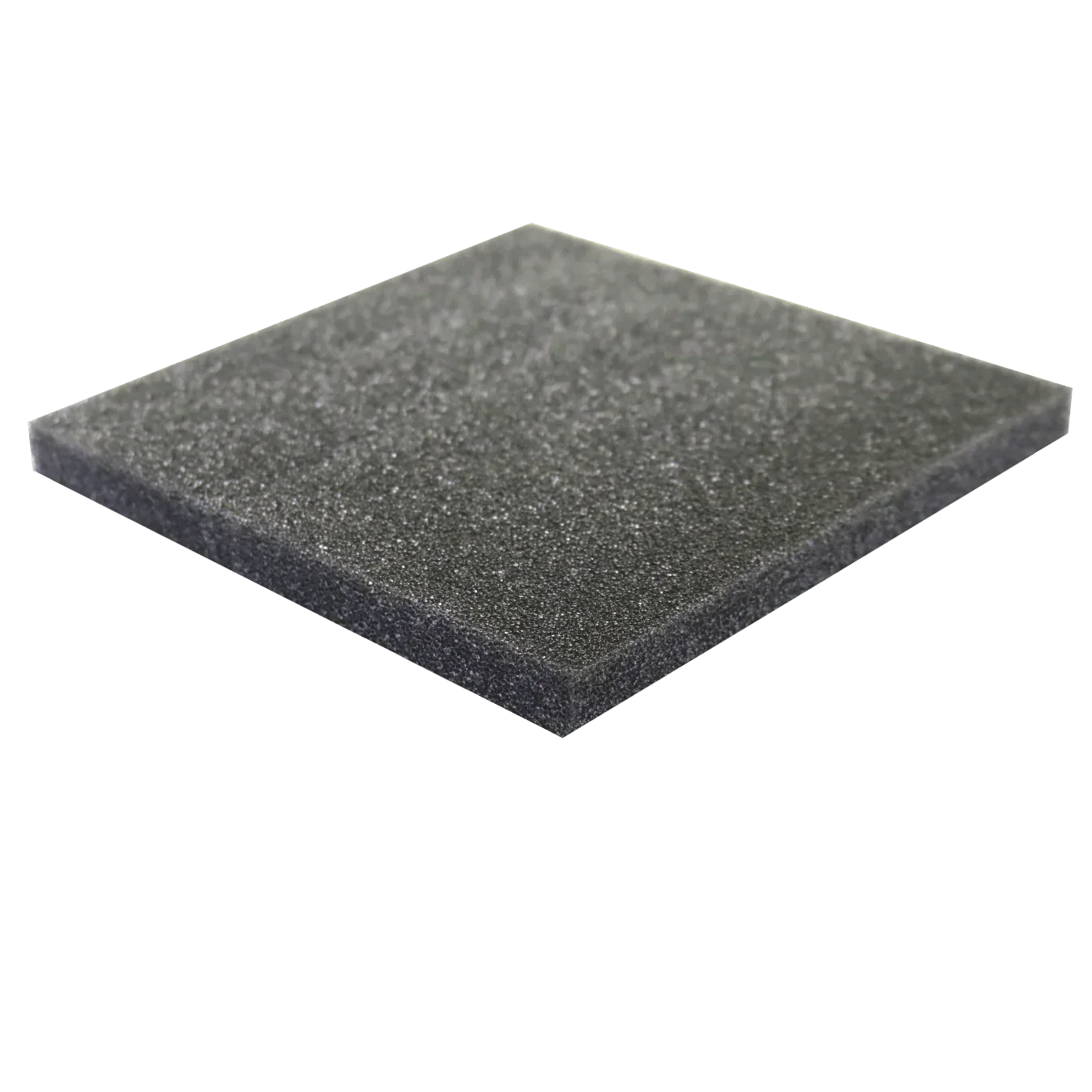

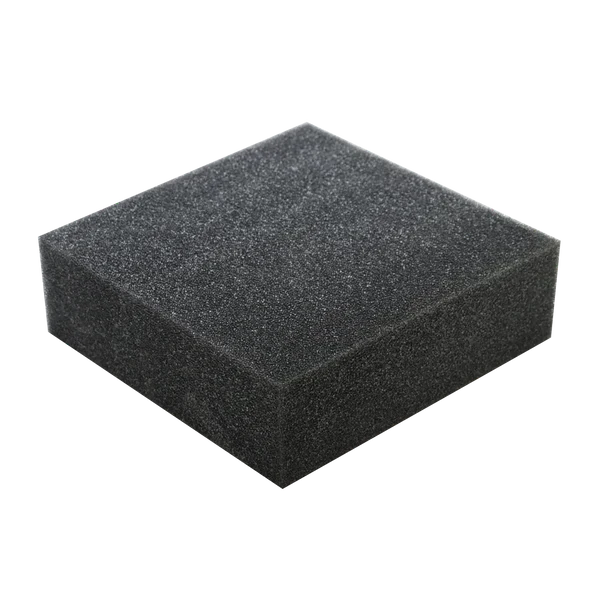

What Makes Polyethylene Foam Special?

Polyethylene foam stands out due to its closed-cell structure, providing excellent thermal insulation, moisture resistance, and durability. These characteristics make it an ideal choice for various construction applications, from insulation to protective packaging. Polyethylene foam sheets, often referred to as PE foam sheets, are lightweight yet durable, offering a cost-effective solution for enhancing energy efficiency and reducing material damage during construction.

Applications in Construction

Polyethylene foam is integrated into construction projects in several key ways, each contributing to the efficiency and durability of the building process.

- Thermal Insulation

- Moisture Barrier

The moisture-resistant properties of polyethylene foam make it an ideal choice for preventing water damage. It acts as a barrier against moisture infiltration, protecting structures from water-related issues such as mold growth, rot, and structural degradation. By ensuring a dry and stable environment within the building envelope, polyethylene foam extends the lifespan of construction materials and maintains the integrity of the structure.

- Protective Packaging

During the construction process, delicate materials and equipment are often at risk of damage.Polyethylene foam sheets serve as protective packaging, cushioning these items and safeguarding them from impacts, vibrations, and other potential hazards. This protection is crucial for maintaining the quality and functionality of materials and equipment, reducing the likelihood of costly repairs or replacements.

- Expansion Joint Filler

Polyethylene foam is used as a filler in expansion joints, which are essential components in construction projects that accommodate building movement. Expansion joints absorb the stress caused by thermal expansion and contraction, seismic activity, and other dynamic forces. By filling these joints with polyethylene foam, builders can prevent cracks and structural damage, ensuring the long-term stability and safety of the building.

Benefits of Polyethylene Foam

Polyethylene foam offers several advantages over traditional materials:

- Durability

Polyethylene foam is highly resistant to chemicals, UV radiation, and physical stress. This resistance ensures that the material maintains its integrity and performance over time, even in harsh environmental conditions. Its durability translates to a longer lifespan for construction components, reducing the need for frequent replacements and maintenance.

- Flexibility

One of the key benefits of polyethylene foam is its flexibility. The material can be easily molded into various shapes and sizes, catering to diverse construction applications. Whether used as insulation, protective packaging, or expansion joint filler, polyethylene foam can be customized to meet specific project requirements. This adaptability makes it an invaluable resource for architects and builders seeking versatile construction solutions.

- Environmental Impact

Polyethylene foam is environmentally friendly, as it is recyclable and often manufactured using eco-friendly processes. This aligns with the growing emphasis on sustainable building practices within the construction industry. By choosing polyethylene foam, builders can reduce their environmental footprint while still achieving high performance in their projects. Additionally, the material's recyclability ensures that it can be repurposed at the end of its lifecycle, contributing to a circular economy.

- Cost-Effectiveness

Polyethylene foam's lightweight nature significantly reduces transportation and installation costs. Its ease of handling and installation allows for faster project completion and lower labor costs. Furthermore, the material's insulating properties can lead to energy savings over a building's lifespan, contributing to lower operational costs. Overall, polyethylene foam provides a budget-friendly option without compromising on quality or performance.

The Role of TCH in Supplying Quality Foam

TCH plays a significant role in the revolution of construction materials by providing high-quality polyethylene foam sheets and other foam products tailored to the industry's needs. With a strong focus on customer satisfaction and product reliability, TCH ensures that construction projects benefit from the best materials available.

TCH has built a reputation for excellence over the years by consistently delivering products that meet stringent industry standards. Their polyethylene foam sheets provide superior performance in various construction applications, including thermal insulation, moisture barriers, and protective packaging.

Impact on Modern Construction

Polyethylene foam is enhancing the construction industry by improving energy efficiency, moisture resistance, and durability of buildings. The material's ability to act as a thermal insulator helps in maintaining consistent indoor temperatures, reducing the need for excessive heating or cooling. This, in turn, leads to significant energy savings and a reduction in overall operational costs.

In terms of durability, polyethylene foam ensures that buildings can withstand various environmental stresses, from chemical exposure to UV radiation. This longevity reduces the need for frequent repairs or replacements, contributing to lower maintenance costs and a longer lifespan for structures.

Real-World Applications

Polyethylene foam is widely used in residential, commercial, and industrial construction projects:

- Residential Buildings: In homes, polyethylene foam provides effective insulation and moisture protection, enhancing comfort and energy efficiency. It is also used to protect household items during construction and renovation.

- Commercial Buildings: For offices and commercial spaces, polyethylene foam contributes to maintaining optimal indoor climates and protecting sensitive equipment. Its use in expansion joints ensures the structural integrity of large commercial buildings.

- Industrial Projects: In industrial settings, polyethylene foam offers robust protection for machinery and materials, ensuring they remain undamaged during construction activities. Its

Polyethylene foam is revolutionizing the construction industry with its unique properties and versatile applications. From insulation to moisture resistance, this material offers numerous benefits, making it a preferred choice for modern construction projects. TCH, as a trusted supplier, ensures that builders have access to high-quality polyethylene foam sheets and products, supporting the industry's evolution toward more efficient, sustainable, and cost-effective building solutions.