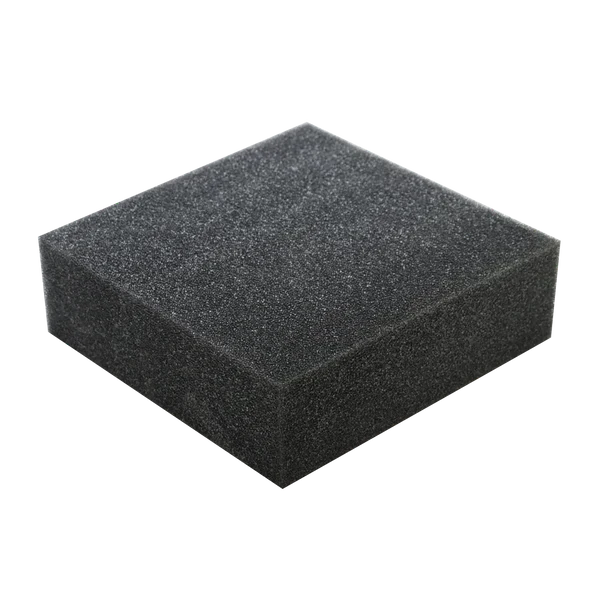

What is convoluted Foam?

Convoluted foam has many commercial applications. Based on customer needs and expectations, it can create various products. The foam material is usually polyurethane, either ether or ester, as they offer incredible flexibility in density and performance. Certain additives are added to the basic convoluted polyurethane foam to create the desired density and thickness based on the application.

Convoluted foam, also known as egg crate foam, is a type of foam that is commonly used for bedding, packaging, and acoustic insulation. It gets its name from its unique shape, which looks like an egg carton. This shape allows the foam to distribute weight more evenly, providing a more comfortable sleeping or sitting experience, excellent air circulation, and better insulation. The convoluted foam is made by convoluting, which involves pressing the foam in a specific pattern while slitting to create the egg crate peaks and valley shape. The peaks and valleys can sometimes be adjusted to produce different-sized foam sheets.

TCH offers 1-1/2" thick Convoluted Ether Foam and 1-1/2" thick Convoluted Ester Foam. Both models can be cut in different sizes according to your requirements by contacting us for custom sizes.

Applications:

Packaging

One of the most common applications of Convoluted foam is packaging fragile items. The foam's shape helps to absorb shock and distribute pressure, protecting delicate items from damage during shipping or transport. Its lightweight and compressible nature makes it easy to store and transport while providing excellent protection. It is ideal for the lid and base layers in Road Cases, camera cases, drone cases, or any case requiring a custom foam insert.

Sound Absorption

Due to the shapes of the peaks and valleys, sound reverberation is absorbed and reduces echoes, providing a softer, clearer, and purer sound. Installing convoluted foam on vertical walls and doors redirects sound away. This makes it ideal for recording studios, home theatres, and other spaces where sound quality is essential.

The benefit of Convoluted Foam packaging

It is usually customized to fit the shape and delicacy of the product placed within.

Shock absorption:

Convoluted foam has excellent protection from bumps and falls. It is a softer, more elastic, and lighter-weight foam most used in cases as a lid and or base layer for impact and shock absorption.

Lightweight:

Weight is a considerable amount for a shipping cost. These foams are lightweight.

Affordability:

Convoluted Foam packaging is affordable and cost-saving material compared with other shipping materials.

Improve Brand Image:

Businesses that ship their products with foam inserts look professional in their customers’ eyes and are industry leaders.

You may also like: