Every industrial project, from power systems to automation controls, depends heavily on the quality and reliability of its hardware. That’s why choosing the right electronic component suppliers is critical. For companies in sectors like energy, transportation, and manufacturing, even a small oversight in sourcing can lead to costly delays, compliance failures, or system downtime.

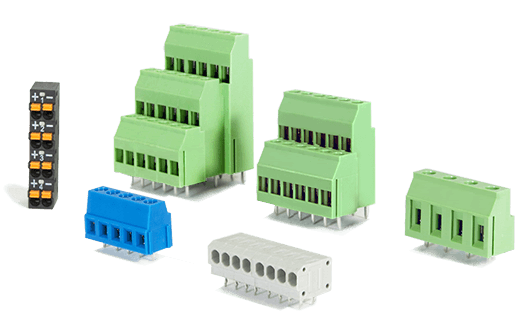

The electronic components TCH specializes in—such as electronic enclosures (Italtronic, exclusive in North America), DIN rail and accessories, power distribution components, and wire and cable hardware—form the backbone of countless systems. When these foundational parts are compromised, the integrity of an entire installation is at risk.

Sourcing isn’t just about finding a component that fits—it’s about ensuring durability, certification, and long-term availability. A trustedelectronic component distributor not only provides the right products but also offers assurance in terms of quality, technical support, and delivery. Yet many buyers make avoidable mistakes during procurement. Below are five of the most common pitfalls and how to avoid them.

1. Overlooking Part Authenticity and Certification

In the world of industrial electronics, authenticity isn’t just a buzzword—it’s essential. Purchasing uncertified enclosures, DIN rail, or power distribution parts can lead to safety risks, non-compliance, and potential liability.

Working with reputable electronic component suppliers is the most effective way to reduce this risk. A reliable electronic component distributor provides products backed by certifications such as UL, CSA, and IEC standards. Authentic components guarantee consistent performance and protect against failures in regulated industries like automation, energy, and medical technology.

2. Ignoring Lead Times and Stock Availability

Industrial projects often run on strict schedules, where even a small delay in sourcing enclosures or wiring hardware can halt progress. A common mistake buyers make is failing to account for lead times and current stock levels.

Electronic component suppliers and distributors provide visibility into inventory and replenishment schedules. Ignoring this information can force buyers to settle for unsuitable alternatives at the last minute. Establishing clear communication with an electronic component distributor helps ensure supply matches demand, preventing costly downtime.

3. Focusing Solely on Price Instead of Quality

It’s tempting to chase the lowest cost, but cutting corners on critical parts like DIN rail, enclosures, or power distribution components can backfire. Low-quality products may not meet safety codes, withstand industrial environments, or offer long-term reliability.

Trusted electronic component suppliers balance affordability with quality. Some also offer anelectronic component kit that bundles essential parts—such as terminals, connectors, or wire management hardware—at competitive rates. These kits save time and reduce sourcing complexity while ensuring quality standards are met. Prioritizing value over just price is key to long-term project success.

4. Neglecting Compatibility and Technical Requirements

Even certified parts can create issues if they don’t meet the exact requirements of a project. For example, an enclosure may not fit the required PCB size, or a DIN rail accessory may not align with an existing system.

An experienced electronic component distributor provides datasheets, engineering support, and cross-reference guidance to confirm compatibility. In many cases, an electronic component kit that has been pre-vetted for technical specifications can streamline sourcing while reducing the risk of mismatched parts. Ensuring every part—whether it’s a cable gland, power block, or rail accessory—meets project standards is crucial for smooth integration.

5. Not Vetting the Supplier’s Reputation and Support Capabilities

A supplier’s role goes far beyond shipping boxes. Buyers who overlook after-sales support often struggle with technical troubleshooting, warranty claims, or urgent replacements.

Reputable electronic component suppliers act as long-term partners. A trusted electronic component distributor offers consistent communication, technical expertise, and flexible solutions to meet evolving needs. Evaluating certifications, testimonials, and long-standing industry relationships helps ensure the supplier will support your project from start to finish.

How to Avoid Common Pitfalls in Electronic Parts Procurement

Sourcing electronic components requires careful planning—from verifying authenticity and availability to ensuring technical compatibility and supplier reliability. Partnering with trusted electronic component suppliers and distributors is the most effective way to secure consistent quality and avoid costly mistakes.

TCH provides a wide range of enclosure and hardware solutions, including Italtronic electronic enclosures, DIN rail and accessories, power distribution components, and wire and cable hardware. Whether you need individual products or a complete electronic component kit, TCH delivers solutions backed by quality, certification, and industry expertise.

Contact TCH today to simplify procurement and keep your projects running smoothly with the right components.

Also read:

The Role of an Electronic Component Distributor in the Supply Chain