Ball Corner

Ball corners are essential in many industries, offering protection, stability, and a polished appearance to various applications. They are often used in conjunction with flight cases, road cases, and enclosures to safeguard valuable equipment and materials. In this blog, we will delve into the various uses and benefits of ball corners in different industries and explore the factors to consider when selecting the right ball corners for your needs.

The Importance of Ball Corners

- Protection: The protruding ball prevents the case walls from touching, avoiding damage during transportation and handling. While in transit, It absorbs shocks and impacts, ensuring the contents remain safe and secure.

- Aesthetic Appeal: Ball corners offer protection and enhance the visual appeal of cases and enclosures, lending a professional and polished look.

- Structural Integrity: By reinforcing the corners and edges, ball corners contribute to the overall strength and durability of cases and enclosures.

- Ease of Assembly: Ball corners can be easily installed using rivets or screws, allowing quick and efficient assembly.

Industries that Benefit from Ball Corners

- Audio/Visual and Entertainment: In the audio/visual and entertainment industries, ball corners are commonly used in flight cases and road cases to protect valuable equipment such as audio mixers, amplifiers, lighting systems, and musical instruments during transportation and storage.

- Trade Shows and Exhibitions: Ball corners are frequently used in trade show booths and exhibition crates to safeguard equipment, materials, and signage while providing a professional appearance.

- Military and Aerospace: Ball corners are used in military and aerospace applications to protect sensitive equipment and instruments during transportation, ensuring the contents remain secure and functional in challenging environments.

- Medical and Scientific Equipment: Ball corners are crucial in safeguarding delicate medical and scientific equipment during transportation and storage, ensuring the equipment remains operational and undamaged.

Selecting the Right Ball Corners

When choosing ball corners for your specific needs, consider the following factors:

- Material: Ball corners are available in various sizes and zinc plated steel thickness depending on the case/enclosure size. Consider the weight, durability, and corrosion resistance required for your application when selecting the material.

- Size and Compatibility: Ball corners come in different sizes and configurations to accommodate various case and enclosure designs. Ensure the ball corners you choose are compatible with your case or enclosure dimensions.

- Load Capacity: Evaluate the weight and pressure the ball corners need to support and choose a suitable design.

- Aesthetic Preferences: Ball corners are available with differentdesign characteristics (standard , stackable, corner/clamp combo, offset legs, shorter legs ) allowing you to select a style that complements the appearance of your case or enclosure.

Different Types:

Large long-leg stacking ball corner

A large long-leg stacking ball corner is a heavy-duty corner protector designed for use with flight cases, road cases, and enclosures. These ball corners provide extra protection and reinforcement to the corners and edges of cases, ensuring they remain strong and secure during transportation and storage.

The long leg design allows for additional stability and support, making it an excellent choice for more extensive and heavier cases. Furthermore, these ball corners are specially designed to enable cases to be stacked on top of one another, maximizing storage space and improving organization.

Made from durable zinc-plated steel, large long-leg stacking ball corners resist corrosion and wear. They are available in various finishes to suit the aesthetic preferences of the case or enclosure.

Small Light Duty Ball Corner

A small light-duty ball corner is a corner protector designed for use with lightweight cases, boxes, and enclosures. These ball corners provide protection and reinforcement for the edges and corners of cases, ensuring they remain intact during transportation and handling.

As the name suggests, small light-duty ball corners are smaller and less robust than heavy-duty ones, making them suitable for lighter and less bulky cases. They are typically made from zinc-plated steel, balancing durability and weight.

These ball corners can be easily installed using screws or rivets. While they may not be as strong as their heavy-duty counterparts, small light-duty ball corners protect your valuable equipment and materials during transport and storage.

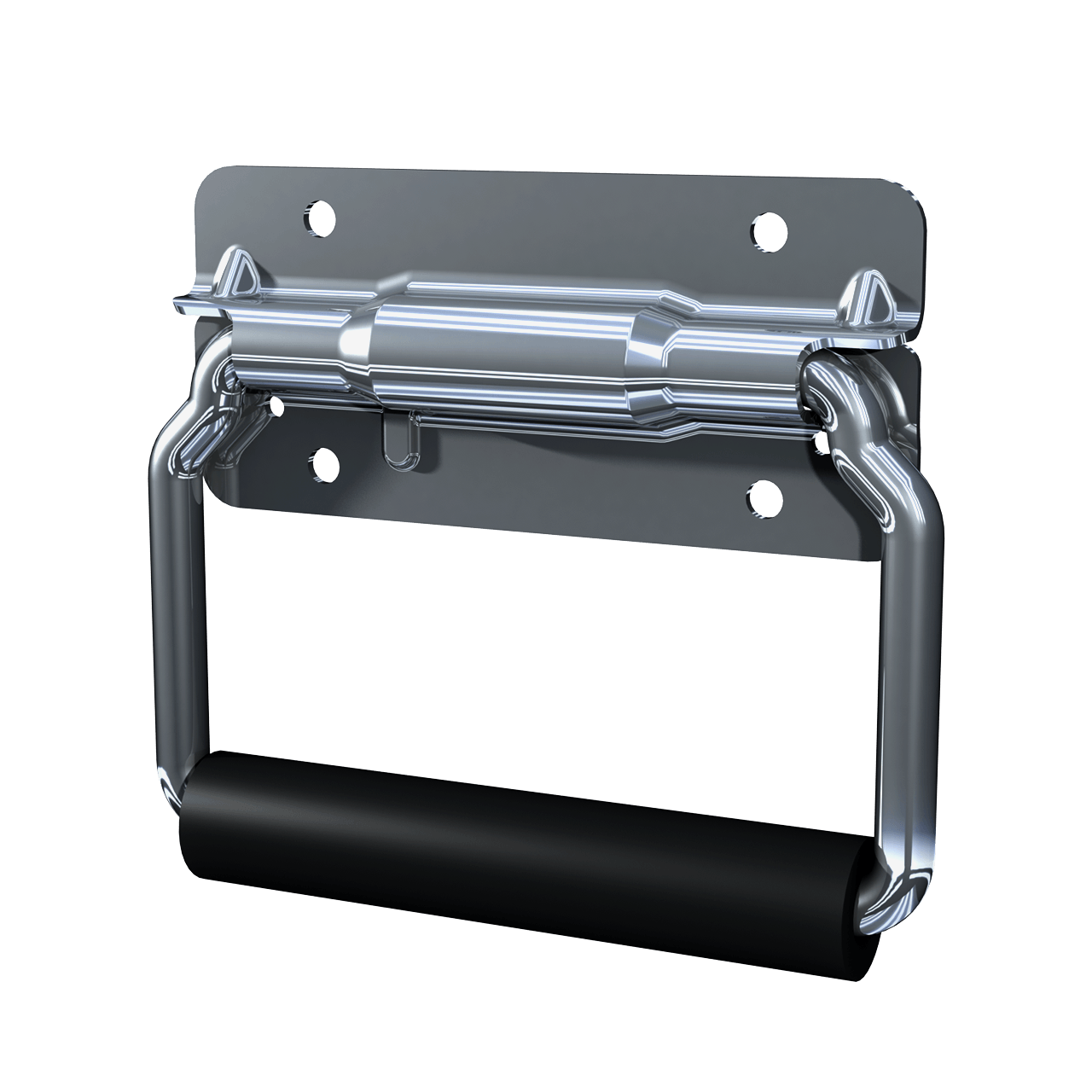

Combination Ball Corner and Clamp

A combination ball corner and clamp is a versatile corner protector that integrates both a ball corner and a clamp into a single unit. This unique design offers increased functionality, making it ideal for use with flight cases, road cases, and enclosures.

The ball corner provides protection and reinforcement for the edges and corners of cases, ensuring they remain strong and secure during transportation and storage. Made from durable zinc-plated steel, these ball corners offer excellent resistance to wear and corrosion.

By offering speed of installation, combination ball corners and clamps can be easily installed using rivets or screws and are available in various sizes to suit the aesthetic preferences of the case or enclosure.

TCH offers different variety of ball and flat corners, casters, and clamps.

You may also like: