Three key characteristics determine the suitability of Building Fasteners like Deck fast Deck Screws, Line Fasteners, or Tek Screws for specific projects. These attributes that define the capabilities of the fastener include:

1. Physical Characteristics

2. Performance Metrics

3. Mechanical Qualities

Physical characteristics

The physical attributes pertain to inherent qualities in the raw material, which remain primarily consistent or undergo minimal alteration during manufacturing. Such innate traits include thermal conductivity, thermal expansion, magnetic susceptibility, density, and electrical resistivity. These factors frequently play a crucial role in choosing the appropriate fastener material.

Performance Metrics

These are attributes engineered into the fastener during its manufacturing process to meet specific functional needs for its intended application. The buckle acquires features such as prevailing torque, driving torque, sealing capabilities, and locking ability through precise control in production. The extent of these characteristics is shaped by both material selection and metallurgical treatments. Performance metrics are adaptable and can be tailored to the design engineer's requirements.

Mechanical properties

Mechanical qualities describe how a fastener responds to applied forces. These characteristics often differ from the raw properties of the material from which the fastener is made. Due to metallurgical treatments and manufacturing techniques, original attributes like flexibility and hardness may transform. Additional mechanical qualities encompass tensile strength, proof load, shear strength, toughness, torsional strength, fatigue strength, and yield strength. The manufacturing and post-treatment processes largely shape these attributes.

The interplay of these three sets of characteristics affects not only the cost of the fasteners but also their functional scope. Their collective attributes determine the types of projects the fastener is suited for and its overall capabilities. Design engineers consider these factors when creating a fastener tailored for a specific need and purpose.

Mechanical Characteristics of Materials

On the other side, the mechanical characteristics of materials dictate the behavior of threaded fasteners when exposed to external forces, commonly referred to as loads. For the design of joints, fasteners are governed by standards and specifications that outline the essential mechanical traits of the materials, including:

1. Strength

2. Toughness

3. Hardness

1) Tensile Strength

Tensile strength quantifies stress in terms of force per unit area. It represents the highest load a material can withstand without breaking when pulled apart.

2) Shear Strength

When selecting threaded fasteners, product designers need to exercise caution. Shear strength describes a material's capacity to withstand forces that could cause its internal layers to slide against one another. For optimal durability, it's advisable to choose fasteners with high shear strength.

Shear strength is commonly assessed in a single or double-shear configuration, typically in a horizontal orientation. A single shear test employs two blades with centrally located transverse holes. One edge secures the fastener in place, while the second blade cuts through the fastener along a parallel plane. In a double shear test, an additional stationary blade is positioned behind the initial shearing edge for added support.

3) Yield Strength

Materials frequently undergo deformation when subjected to stress. Its yield strength should be evaluated to determine the point at which a material will experience permanent deformation. In the context of a bolt, yield strength is characterized as the pulling force that leads to a specific level of irreversible distortion within the fastener.

4) Hardness

The material’s ability to withstand indentation and abrasion.

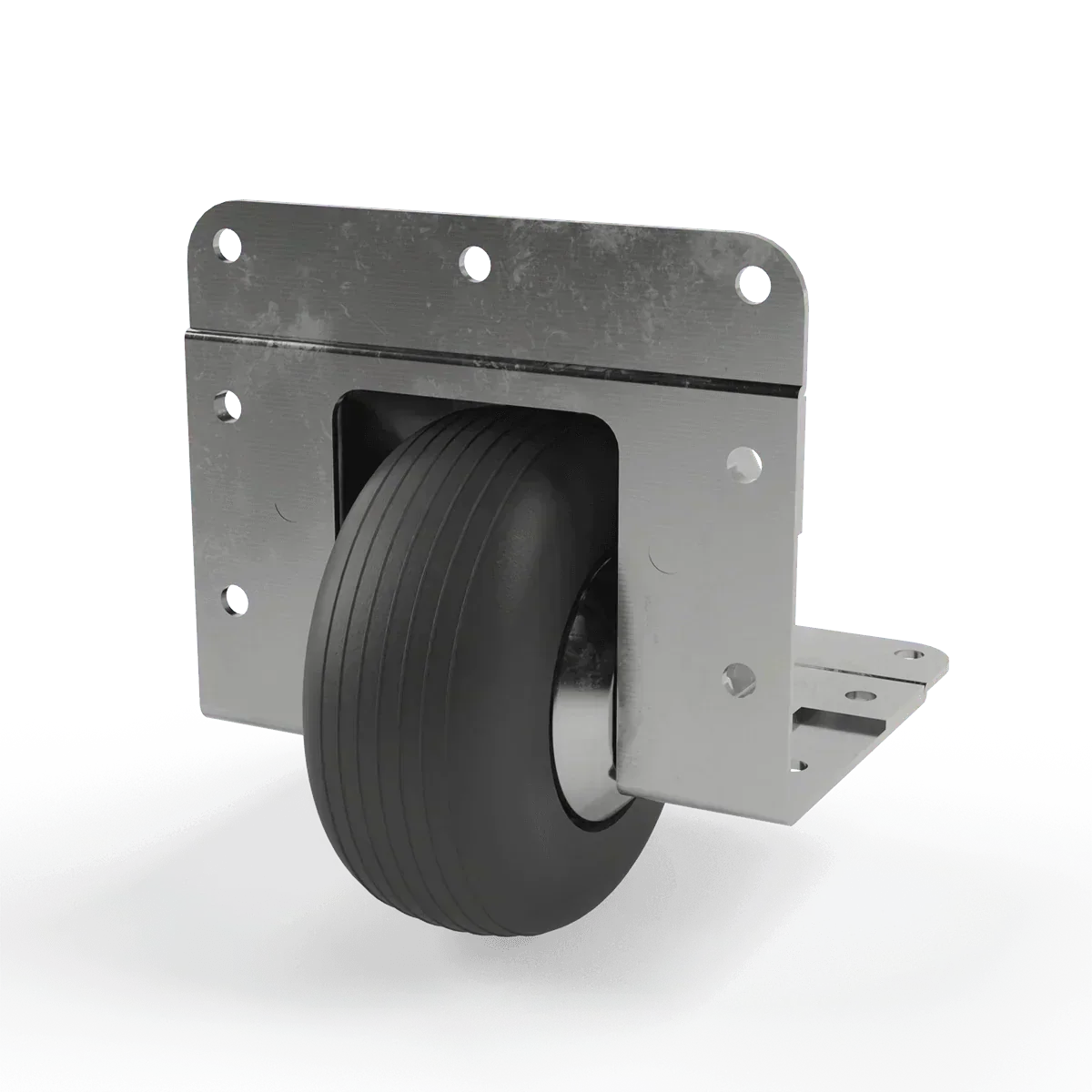

What is a fastener?

A fastener is a mechanical device, either temporary or permanent that firmly joins two surfaces or items. Temporary fasteners can be detached without harming the linked materials. On the other hand, taking out permanent fasteners may demand significant effort and could damageremovingsetting the bonded areas. Permanent fasteners are intended to provide a durable and secure connection.

Fasteners encompass a variety of items such as screws, nails, nuts, bolts, and washers, available in diverse sizes, forms, and designs. They are among the most commonly utilized tools in constructing, assembling, and setting numerous products and industrial machinery.

Southco Offers a Variety of Fasteners:

Captive Screws

- Stays secure to the panel, preventing loss and protecting sensitive electronics.

- Tool recess, thread size, and installation options to suit any application.

- Spring ejection and self-aligning float provide easy installation.

DZUS® Quarter-Turn Fasteners

- Quickly secures and releases with a 90-degree turn.

- Stays captive to the panel, providing ease of use and preventing lost hardware.

- Provides a robust and consistent clamping force with repeated operation.

Quick Access fasteners

- Provides quick access for hinged or removable panels.

- Latches into thru or blind holes.

- Locates sliding panels.

Rivets

- Available in six different diameters and numerous lengths.

- Materials and sizes to suit a range of environmental and strength requirements.

- Tamper-resistant/tamper-evident designs resist being driven through or drilled out.

Inject/Eject Mechanisms

- Ergonomic insertion, extraction, and locking of electronic modules.

- Adheres to industry standards for robustness and hot swap capability.

- Wide range of designs to match popular connector pin densities.

Gaskets

- Seal out dust and moisture.

- Minimize rattles due to vibration.

- Compensate for surface contour irregularities.